Devices & Fixtures

Devices & Fixtures

Devices & Fixtures

Devices and fixtures are often one of a kind or limited production items intended for a specific purpose. We have expertise in devices and fixtures including test fixtures, assembly fixtures, anti-tamper devices, and factory safety interlock devices.

Devices and fixtures are often one of a kind or limited production items intended for a specific purpose. We have expertise in devices and fixtures including test fixtures, assembly fixtures, anti-tamper devices, and factory safety interlock devices.

Devices and fixtures are often one of a kind or limited production items intended for a specific purpose. We have expertise in devices and fixtures including test fixtures, assembly fixtures, anti-tamper devices, and factory safety interlock devices.

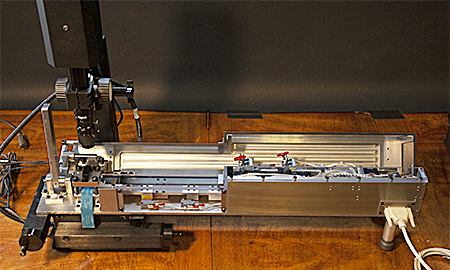

Test Fixture for Laparoscopic Scissors

This semi-automated test fixture was designed and fabricated for a surgical device manufacturer. The mechanical design and fabrication included a feed and tensioning mechanism, a safety interlock cover, and part holding nests with precise clamping. The electronic design and assembly included stepper motors, force and position sensors, power supplies, a microcontroller, measurement circuitry, and status displays. The system design also included a digital microscope for close examination of each scissor as it made a test cut.

See more information about this project at Biotech & Medical.

This semi-automated test fixture was designed and fabricated for a surgical device manufacturer. The mechanical design and fabrication included a feed and tensioning mechanism, a safety interlock cover, and part holding nests with precise clamping. The electronic design and assembly included stepper motors, force and position sensors, power supplies, a microcontroller, measurement circuitry, and status displays. The system design also included a digital microscope for close examination of each scissor as it made a test cut.

See more information about this project at Biotech & Medical.

This semi-automated test fixture was designed and fabricated for a surgical device manufacturer. The mechanical design and fabrication included a feed and tensioning mechanism, a safety interlock cover, and part holding nests with precise clamping. The electronic design and assembly included stepper motors, force and position sensors, power supplies, a microcontroller, measurement circuitry, and status displays. The system design also included a digital microscope for close examination of each scissor as it made a test cut.

See more information about this project at Biotech & Medical.

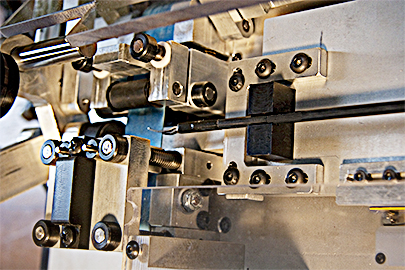

Laser Etching Fixture for Surgical Devices

This project included mechanical design and fabrication of the aluminum plate enclosure that supports the laser, a safety interlock to automaticlly shut down the laser if the door is open, laser-safe windows, a precision slide mechanism and parts holding nest platform, and an air filter.

Several of these fixtures were fabricated.

See more information about this project at Biotech & Medical.

Laser Etching Fixture for Surgical Devices

This project included mechanical design and fabrication of the aluminum plate enclosure that supports the laser, a safety interlock to automaticlly shut down the laser if the door is open, laser-safe windows, a precision slide mechanism and parts holding nest platform, and an air filter.

Several of these fixtures were fabricated.

See more information about this project at Biotech & Medical.

Laser Etching Fixture for Surgical Devices

This project included mechanical design and fabrication of the aluminum plate enclosure that supports the laser, a safety interlock to automaticlly shut down the laser if the door is open, laser-safe windows, a precision slide mechanism and parts holding nest platform, and an air filter.

Several of these fixtures were fabricated.

See more information about this project at Biotech & Medical.

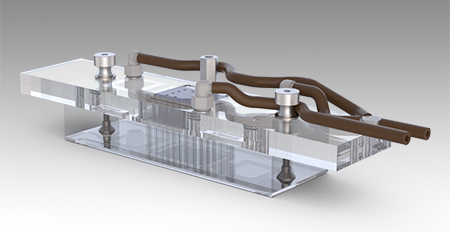

Slide Holding and Positioning Fixture

This project involved the design and fabrication of a CNC milled polycarbonate plate to act as a vacuum manifold to hold a cast rubber block with thru channels, and a glass slide underneath it.

See more information about this project at Biotech & Medical.

Slide Holding and Positioning Fixture

This project involved the design and fabrication of a CNC milled polycarbonate plate to act as a vacuum manifold to hold a cast rubber block with thru channels, and a glass slide underneath it.

See more information about this project at Biotech & Medical.

Slide Holding and Positioning Fixture

This project involved the design and fabrication of a CNC milled polycarbonate plate to act as a vacuum manifold to hold a cast rubber block with thru channels, and a glass slide underneath it.

See more information about this project at Biotech & Medical.

Safety Enclosure for an Electro-Hydraulic Press

A manufacturer of warehouse robots needed a safety enclosure designed, fabricated, and installed on a 25 ton electro-hydraulic press. The enclosure requirements included dual interlocks, positive engagement upon closing, a maximum of visibility into the enclosure, and an adjustable counterbalance spring assist for raising and lowering the enclosure door.

The mechanical design and fabrication included machining aluminum parts, cutting and joining aluminum extrusions, and making the polycarbonate front, back, and side windows.

Safety Enclosure for an Electro-Hydraulic Press

A manufacturer of warehouse robots needed a safety enclosure designed, fabricated, and installed on a 25 ton electro-hydraulic press. The enclosure requirements included dual interlocks, positive engagement upon closing, a maximum of visibility into the enclosure, and an adjustable counterbalance spring assist for raising and lowering the enclosure door.

The mechanical design and fabrication included machining aluminum parts, cutting and joining aluminum extrusions, and making the polycarbonate front, back, and side windows.

Safety Enclosure for an Electro-Hydraulic Press

A manufacturer of warehouse robots needed a safety enclosure designed, fabricated, and installed on a 25 ton electro-hydraulic press. The enclosure requirements included dual interlocks, positive engagement upon closing, a maximum of visibility into the enclosure, and an adjustable counterbalance spring assist for raising and lowering the enclosure door.

The mechanical design and fabrication included machining aluminum parts, cutting and joining aluminum extrusions, and making the polycarbonate front, back, and side windows.

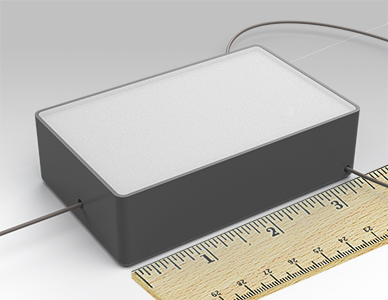

Secure Passive RFID Seal

For a client with specialized item monitoring and security needs, we have designed and fabricated several different families of secure passive RFID devices with anti-tamper, tamper-evident, and self-destruct features.

This seal includes a permanently locking security cable which if cut or forced, will change the output of an internal passive RFID tag and will also provide a visual indication of tampering.

Most parts were CNC milled from stainless steel, aluminum, or plastic, or were 3D printed.

Secure Passive RFID Seal

For a client with specialized item monitoring and security needs, we have designed and fabricated several different families of secure passive RFID devices with anti-tamper, tamper-evident, and self-destruct features.

This seal includes a permanently locking security cable which if cut or forced, will change the output of an internal passive RFID tag and will also provide a visual indication of tampering.

Most parts were CNC milled from stainless steel, aluminum, or plastic, or were 3D printed.

Secure Passive RFID Seal

For a client with specialized item monitoring and security needs, we have designed and fabricated several different families of secure passive RFID devices with anti-tamper, tamper-evident, and self-destruct features.

This seal includes a permanently locking security cable which if cut or forced, will change the output of an internal passive RFID tag and will also provide a visual indication of tampering.

Most parts were CNC milled from stainless steel, aluminum, or plastic, or were 3D printed.

design@design-innovation.org 781-883-5666

design@design-innovation.org 781-883-5666

design@design-innovation.org

781-883-5666